Manufacturers today are leaning on AI to tackle everyday production challenges, smooth out workflows, and speed up smarter decisions. From keeping an eye on quality in real time to simplifying supply chains, AI is helping teams work with more accuracy and ease. With the right integration, companies gain agility and stay a step ahead in a competitive market.

By bringing AI into manufacturing, businesses can cut down on repetitive tasks, reduce downtime, and even spot equipment problems before they happen. These tools also make it easier to analyze large amounts of data, spot patterns, and quickly adjust to market shifts. The result is a smarter, more adaptive production environment that fuels both growth and innovation.

AI is reshaping the manufacturing industry with advanced automation, predictive analytics, and real-time process optimization. It empowers manufacturers to boost efficiency and cut operational costs at scale.

AI improves production efficiency by up to 30%.

Predictive AI maintenance cuts equipment downtime by up to 50%.

AI-driven defect detection increases product quality accuracy by 90%.

AI adoption in manufacturing reduces operational costs by 20–40%.

We offer cutting-edge AI manufacturing solutions tailored to address every operational challenge, whether it's process automation, quality control, or innovation. Our development-first approach ensures scalable, efficient, and intelligent manufacturing transformation across all touchpoints.

We develop AI-based manufacturing solutions that monitor equipment health in real-time, predict failures, and automate maintenance scheduling. Our predictive systems help manufacturing units significantly reduce unplanned downtime and extend machinery life while lowering maintenance costs.

With expertise as a manufacturing AI software development company, we build intelligent automation frameworks that power smart factories. From IoT sensor integration to robotic systems, our solutions optimize workflows, minimize human error, and ensure seamless operations.

We create AI-driven manufacturing solutions that leverage computer vision and deep learning to detect defects with high accuracy. These solutions improve product reliability, minimize waste, and support manufacturers in meeting strict compliance and safety standards.

Our team develops AI solutions for manufacturing that bring visibility and predictive intelligence into supply chain operations. By forecasting demand, reducing lead time, and optimizing Manufacturing, we enable smarter supply chain decisions across global networks.

As a trusted AI manufacturing software development partner, we deliver AI-powered planning tools that optimize production schedules in real time. These solutions dynamically adapt to resource availability, capacity constraints, and market changes for peak efficiency.

We harness generative AI in manufacturing to build intelligent product development platforms. From idea generation to rapid prototyping, our solutions accelerate innovation, reduce R&D cycles, and help you bring smarter products to market faster.

Our advanced AI manufacturing solutions are built to meet the unique challenges of each industry segment. Whether it's speed, precision, compliance, or innovation, we develop scalable AI systems for every vertical.

We build AI-powered manufacturing solutions that enhance vehicle assembly, predict maintenance needs, and improve supply chain efficiency. Our systems optimize quality, reduce defects, and accelerate production cycles.

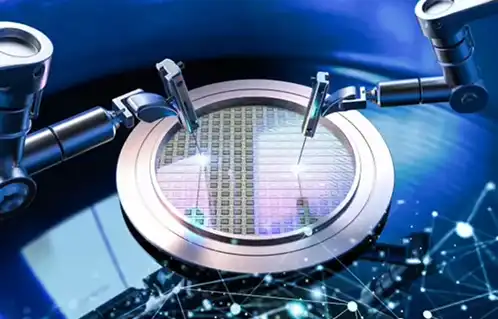

Our AI solutions in manufacturing for semiconductors focus on yield prediction, defect detection, and process automation. These tools ensure precision, speed, and minimal material waste throughout chip fabrication.

We develop AI manufacturing solutions that ensure regulatory compliance, accelerate drug production, and maintain sterile environments. AI helps predict outcomes, automate testing, and streamline R&D processes.

Using AI technologies for manufacturing, we enable real-time monitoring, waste reduction, and predictive maintenance in food plants. Our systems improve quality control, consistency, and food safety compliance.

Our AI-based manufacturing solutions streamline fabric inspection, automate cutting, and manage demand forecasting. These innovations speed up production while reducing errors and material waste in textile plants.

We deliver custom manufacturing AI software solutions that manage chemical blending, monitor reactions, and enhance worker safety. AI supports precision operations and predictive analytics in chemical processing.

From ideation to execution, our streamlined process ensures every AI solution for manufacturing is tailored, scalable, and built for real-world results. We blend innovation, precision, and agile delivery at every stage.

We define product goals and build AI-powered models tailored to your manufacturing needs.

We simulate workflows and production environments using AI for accurate forecasting and optimization.

We deploy AI agents and IoT systems to automate and digitize every factory process seamlessly.

We integrate intelligent control systems to monitor quality and manage production in real time.

We provide ongoing monitoring, data insights, and AI refinements to keep operations optimized.

JPLoft combines AI, machine learning, and other emerging technologies to craft scalable solutions, giving your business a competitive edge. Our teams' expertise covers a vast range of technologies, setting us apart from other companies.

We integrate the latest technologies with AI in manufacturing to deliver intelligent, future-ready systems. These advanced tools enhance precision, automation, and real-time responsiveness across all production workflows.

Our AI solutions use computer vision to detect defects, monitor processes, and ensure quality. A Computer vision development company enables real-time inspection and high-accuracy automation.

We deploy robotics enhanced with artificial intelligence in manufacturing to automate assembly, packaging, and sorting. These systems improve speed, safety, and flexibility on the production line.

NLP helps machines understand human instructions in manufacturing. A skilled NLP development company enables smarter HMIs, automated reporting, and better maintenance documentation tools for streamlined operations.

Generative AI supports manufacturing with design iterations, simulations, and product customization. Gen AI development services reduce R&D time, speed innovation, and drive personalized production efficiently.

AI cybersecurity tools detect threats, protect manufacturing data, and adapt in real-time. An AI app development company ensures resilience, safeguards networks, and prevents operational disruptions.

We build predictive platforms that forecast equipment issues before failure occurs. This helps in planning proactive maintenance, reducing costs, and preventing production halts.

At JPLoft, we blend deep industry expertise with innovative AI development to deliver intelligent, scalable manufacturing solutions. From strategy to execution, our team ensures seamless integration, measurable impact, and long-term success. Trust us to be your reliable AI manufacturing software development partner.

We understand the manufacturing ecosystem and develop AI solutions aligned with real-world industrial needs and performance goals.

We offer custom manufacturing AI software solutions built from scratch to meet your specific business workflows and technology requirements.

Trusted by global manufacturers, our portfolio showcases successful deployments of intelligent and scalable AI solutions for manufacturing.

From ideation to post-launch optimization, we offer end-to-end AI manufacturing solution development services under one roof.

We integrate the latest in AI, robotics, and analytics to future-proof your manufacturing operations.

Our commitment goes beyond delivery, offering 24/7 monitoring, updates, and support to maximize your ROI from AI adoption.

Connect with a leading AI manufacturing company and unlock scalable, intelligent solutions tailored to your production goals.

AI in manufacturing refers to the use of artificial intelligence technologies, such as machine learning, computer vision, and predictive analytics, to automate processes, improve decision-making, and optimize operations. It enables machines and systems to learn from data, adapt in real-time, and perform tasks with higher efficiency and precision.

The key benefits of AI in manufacturing include increased operational efficiency, reduced downtime, better quality control, lower costs, and faster time to market. AI also enhances safety, enables real-time monitoring, and supports smart decision-making by processing large volumes of data across supply chains and production units.

Predictive maintenance uses AI algorithms to analyze equipment performance data and forecast potential failures before they happen. This approach minimizes unplanned downtime, extends the lifespan of machines, and ensures smoother operations, leading to significant cost savings and improved productivity across the manufacturing workflow.

No. While large enterprises often lead adoption, AI manufacturing solutions are increasingly scalable and accessible to small and medium-sized businesses. Tailored AI systems can address specific pain points, whether it’s automating inspections, managing inventory, or improving production planning, making AI adoption viable at any scale.

The development timeline for an AI manufacturing solution varies depending on project complexity, data availability, and required integrations. On average, a custom solution may take 3–6 months, including discovery, model training, deployment, and testing. JPLoft ensures efficient delivery through agile processes and expert planning.

JPLoft combines deep domain expertise with cutting-edge technologies to deliver robust, scalable, and intelligent AI manufacturing solutions. Our custom development approach, full-cycle support, and proven success across industries make us a trusted partner for manufacturers looking to innovate and grow through AI.

Discover the stories behind the success and the partnerships we cherish.

Empowering 1000+ clients globally with innovative Web & Mobile App Development solutions.

Years of experience

Projects Successfully Completed

Users Trust Our Clients' Platforms

Secured by Our Clients

Every project tells a story of innovation, and mutual success.

Get the latest updates on development insights, technologies and trends.

United States(Denver, New York, Dallas, Chicago, Texas, Austin), United Kingdom, Australia(Melbourne, Sydney, Adelaide, Brisbane, Perth, Canberra), Singapore, Canada, United Arab Emirates(Dubai), Saudi Arabia, Netherlands, Switzerland, France, Africa, Europe, Middle East, etc.